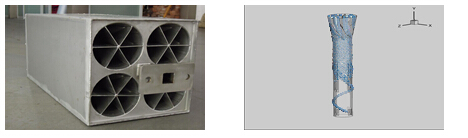

The Swirltube Axial Cyclone is a stainless steel tube with a swirler at the inlet and longitudinal slits in the tube wall. Liquid is separated on the vanes of the swirler by impaction of droplets on the swirler and on the tube wall as a result of the centrifugal forces induced by the swirling gas flow.

Re-entrainment of this liquid is prevented by draining the film via the slits to the lqiuid collection chamber outside the tube. To ensure the proper functioning of the Swirltube it is essential that some gas is also bled through these slits. This gas leaves the liquid collection chamber via the secondary outlets at the top of the Swirldeck assembly. Performance can be improved by using a secondary KnitMesh mist eliminator to separate entrainment from the gas leaving the secondary outlets. The main fraction of the gas leaves the Swirltube via the primary gas outlet at the top. Drain pipes guide the liquid, collected in the space between the tubes and on the upper cover of the Swirldeck, to below the liquid level.

Scaling-up of a separator equipped with a swirldeck is done simply by increasing the number of swirltubes proportional to the gas flow in the separator.

Performance Guarantee-Swirltube Axial Cyclones

Liquid removal efficiencies:

·Outlet gas will contain less than 0.10 gallon of entrained liquid per million standard cubic feet of gas passed through the separator

·100% of all droplets 8-microns in diameter and larger

·99% of 4- to 6-micron droplets

·98% of 2- to 4-micron droplets

Advantages

·Offers a high gas / liquid separation efficiency at high operating pressures and with complex fluids

·Handles high flow throughput

·Handles high liquid loading

·Requires a low pressure drop for relatively high droplet separation efficiency

·Provides a high turndown ratio

·Reduces or eliminates the production of foam, thereby reduces OPEX by reducing the need for anti-foaming chemicalsRobust construction

·Offers a wide operational range

·Reduces the vessel size on a new build project

·Allows a greater fluid throughput for a set vessel size, on a revamp project

·Non-clogging design makes it suitable for installations with medium/high solids loading

·Easy to install in both new and existing separators

·No moving parts, so no maintenance.

Application

·Production Separators

·Test Separators

·Gas Scrubbers

·Gas Knock-out Drums

·Slug Catchers

·Flash Drums

·Process Vessels and Columns

·Floating Production Units (FPUs)

|