|

The role of the demisting device is to remove small liquid droplets from the gas stream in order to protect any downstream equipment such as compressors and other processing equipment, to reduce carry-over and loss of any valuable chemicals, and to prevent pollution.

Demisting devices come in many different forms and include Filters, Mesh Type (or mesh pads), Vane Type (or vane packs), and Cyclonic Types. For all of these devices, the basis of the operation will be flow velocity dependent. Consequently, the choice of demisting device must be made according to the required separation efficiency, the predicted droplet size distribution, and the gas velocity. The correct selection of demisting device can allow a reduced vessel diameter to be used, together with some reduction in the weight and the space required. In turn, these changes will produce a reduction in Capital Expenditure as well as an improvement in the overall performance of the separation system. Lower levels of foaming will reduce the requirement for expensive chemicals and offer a reduction in Operating Expenditure.

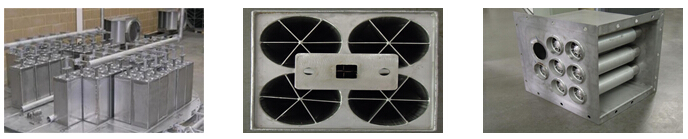

It is important to make the correct choice of demisting device, dependent on the operating conditions (i.e. pressure levels, possibility of wax formation, solids loading, foaming, etc.) and physical properties (i.e. liquid density, viscosity, surface tension, etc.). we have an extensive range of the more traditional demisting devices, covering Mesh Types, Vane Packs and advanced Axial Cyclonic Devices.

Advantages

·Increases the gas/liquid separation efficiency

·Reduce the vessel size, thus reducing capital expenditure

·Reduce foaming, thus reducing operating expenditure by reducing the usage of anti-foaming chemicals

·Increase the gas throughput.

Traditional Demisting Devices

·Mesh Type Demisting Devices

·Vane Packs Demisting Devices

Advanced Axial Cyclonic Devices

·Swirltube Axial Cyclones

·Highspeed Axial Cyclones

|