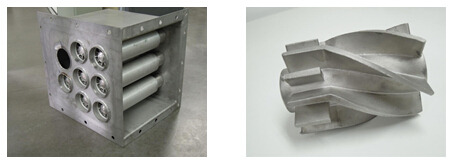

The Highspeed Axial Cyclone provides a high degree of separation of fine droplets and dust even at high operating pressures. It can be positioned vertically or horizontally within a separator vessel.

Due to its high capacity it is ideal for retrofitting into existing separators when higher throughputs are required with improved efficiency. In new build applications these axial cyclones will result in significantly smaller vessels and hence give considerable weight savings and cost reductions.

The Highspeed Axial Cyclone is extremely efficient, even at higher pressures when vane packs lose their performance, and also when processing liquids with a low surface tension.

INLET ZONE – The incoming gas containing liquid droplets and/or solid particles is accelerated at high speed into a cyclonic swirl so that the heavy contaminants are flung to the cyclone tube walls.

REJECT SEPARATION ZONE – In the main body the contaminants form a film or layer at the tube wall and are swept upwards with the gas due to the combined cyclonic action and longitudinal drag force.

OUTLET ZONE – The top of each element is supplied with a centrifugal separator cap which captures the liquid film and sends it falling to the tray deck outside the element tube. Captured liquid drains from the tray deck via a down-comer pipe into the vessel’s liquid sump for disposal.

HORIZONTAL INSTALLATIONS – For higher contaminant loadings the cyclones are laid horizontally and the elements are sealed at each end within a free-draining box. A small amount of carrier gas is re-circulated.

Performance Guarantee-Highspeed Axial Cyclones

Liquid removal efficiencies:

·Outlet gas will contain less than 0.10 gallon of entrained liquid per million standard cubic feet of gas passed through the separator

·100% of all droplets 10-microns in diameter and larger

·99% of 6- to 8-micron droplets

·98% of 4- to 6-micron droplets

Advantages

·High gas throughput capacity

·Typically?2/3?of the size of vane pack KO drums

·Typically?1/3?the size of wire mesh KO drums

·Major savings in vessel weight and cost

·Excellent performance at very high pressures

·Tolerates solids; motion; cures foaming

·Low maintenance

·Available in stainless steel or plastics

·Excellent turndown with pre-coalescer

·Low pressure drop (30 mbar)

·Easy to install in both new and existing separators

·No moving parts, so no maintenance.

Application

·Glycol and amine mist eliminators in HP gas treaters

·Droplet removal from distillation or absorber towers

·KO Drums and separators

·Compressor suction and discharge scrubbers

·High velocity discharge vents

·Gas Scrubbers

|