Due to the gently curved nature of the vane surfaces and diffuser-type area changes within our proprietary Vane Type Inlet Device, the flow velocity reduces steadily from inlet to outlet; in turn, this lessens the potential for droplet shatter.

The Vane Type Inlet Device can be used for inlet momentums factor of 4~5 higher than half-open pipe inlets. Typically, half-open pipe inlets are used for momentums (ρV2, where ρ is bulk density, kg/m3, and V is bulk velocity, m/s) less than 1,500 Pa. For applications of inlet momentum typically less than 9 kPa, a vane type inlet device can be used.

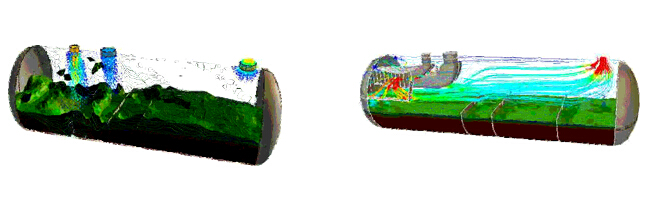

The Vane Type Inlet Device distributes the fluids evenly across the separator, to minimise mal-distribution effects which may lead to excessive liquid carryover in the demisting device, caused by a combination of localised elevated gas velocity levels and high liquid loading at the inlet face of the demisting device. Uniformity of the flow will also minimise any re-entrainment from the liquid surface, and minimise flow control problems.

The fluids are “sliced” off to either side while flowing through the inlet device. The spacing between the blades typically has been designed using computational fluid dynamics (CFD) to achieve uniform flow. Because the area of the vane inlet is several times larger than the inlet nozzle, the fluid velocities are much smaller, allowing for good gas/liquid separation as well as smooth entry into the vessel.

Advantages

·Separates the bulk liquids present within the inlet stream

·Reduces the momentum of the inlet stream, thus minimising the potential for droplet shatter

·Distributes the gas flow evenly over the downstream demisting equipment

·Minimises the effect of channelling through the downstream demisting equipment

·Wide operational range – typically, providing 100% turndown

·Reduces the likelihood of re-entrainment of liquid from the liquid surface

·Reduces any turbulence and re-circulation within the liquid section

·Provides a minimal pressure drop

·Reduces the size of the inlet nozzle on a new build project

·Allows a greater fluid throughput for a set nozzle size on a revamp project

·Easy to install in new and existing separators

·No moving parts, thus no maintenance.

Application

·Gas Scrubbers

·Production Separators

·Gas Knock-Out Drums

·Distillation, & Absorption Columns

·Flare Knock-Out Drums

·Floating Production Units (FPUs)

|